Principle

Reverse Osmosis Desalinators

Reverse osmosis is a membrane process that removes both organic salts and micro organisms in the brackish and sea water.

The purification process is very simple: under-pressure water is fìltered through a membrane. The resulting product is called permeated, the water obtained is a thresh water that has been completely sterilized since membranes do not allow single sail molecules pass through, they are even less likely to let bacteria and viruses, which have bigger dimensions, penetrate.

The remaining part is more concentrated water, not utilized.

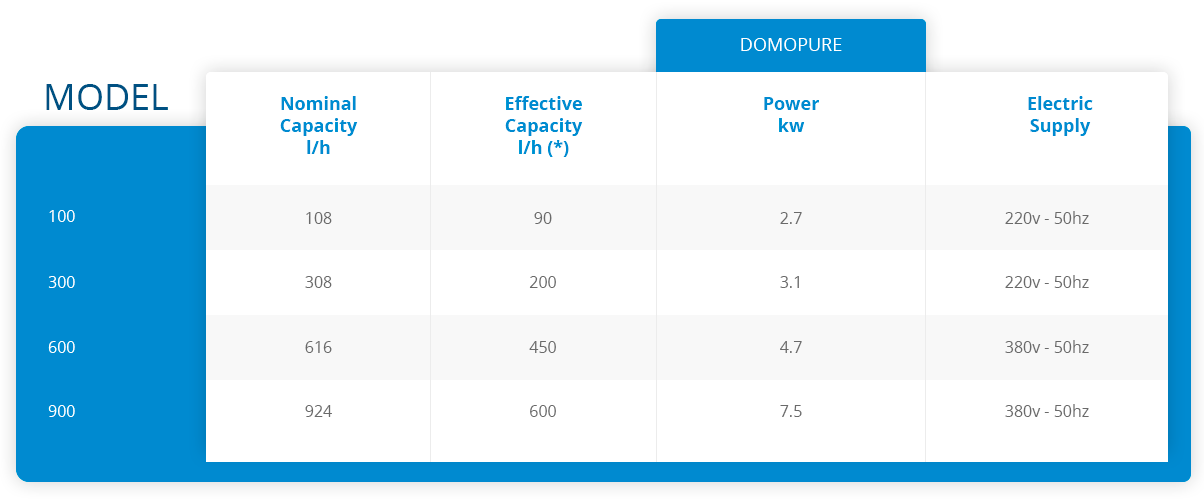

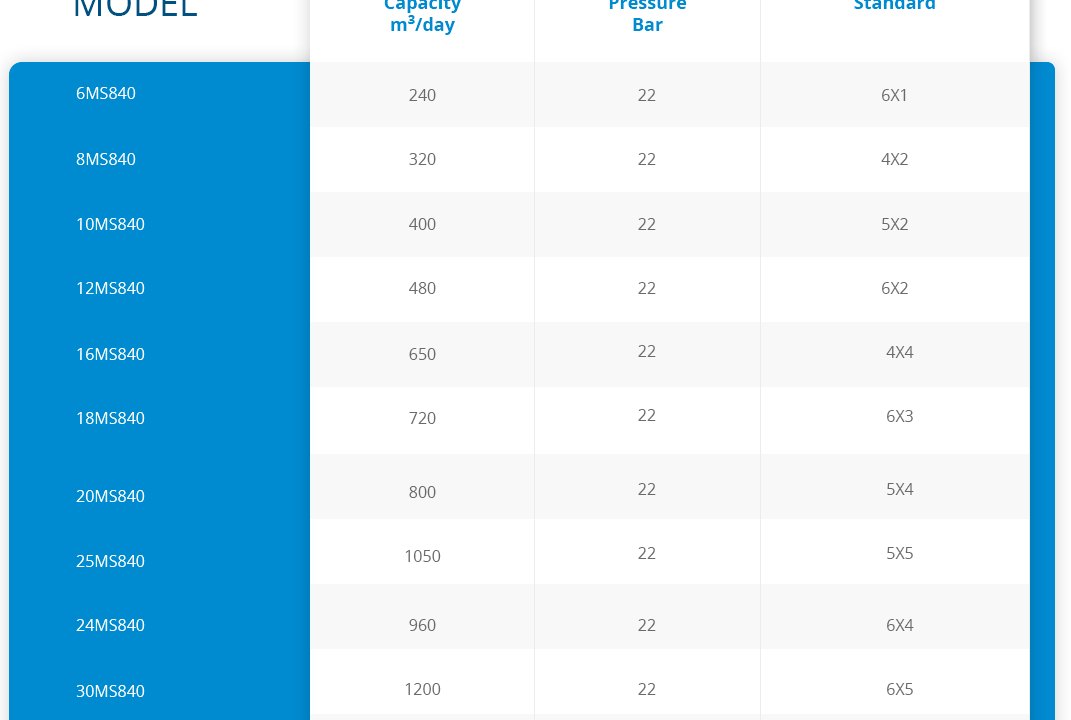

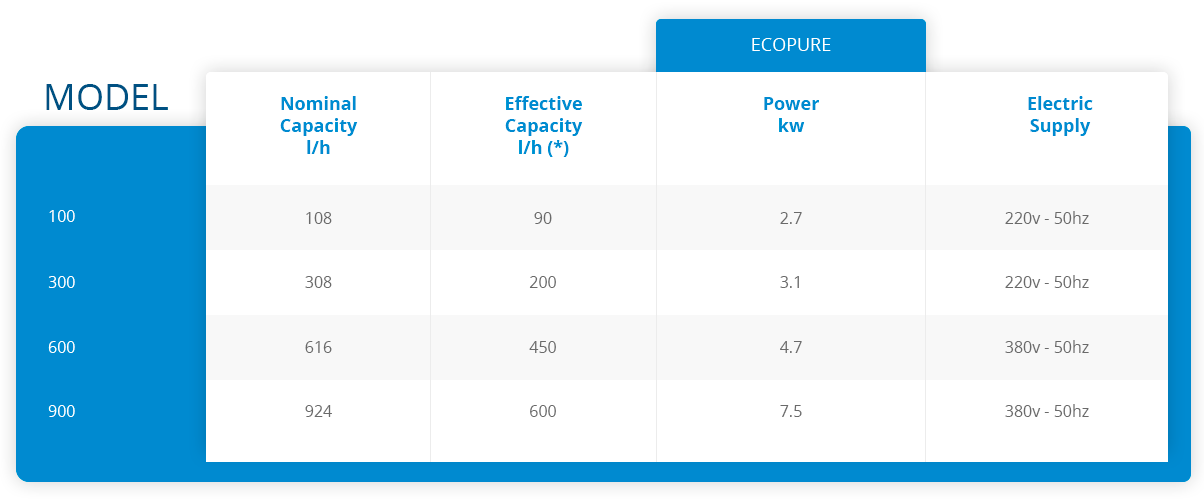

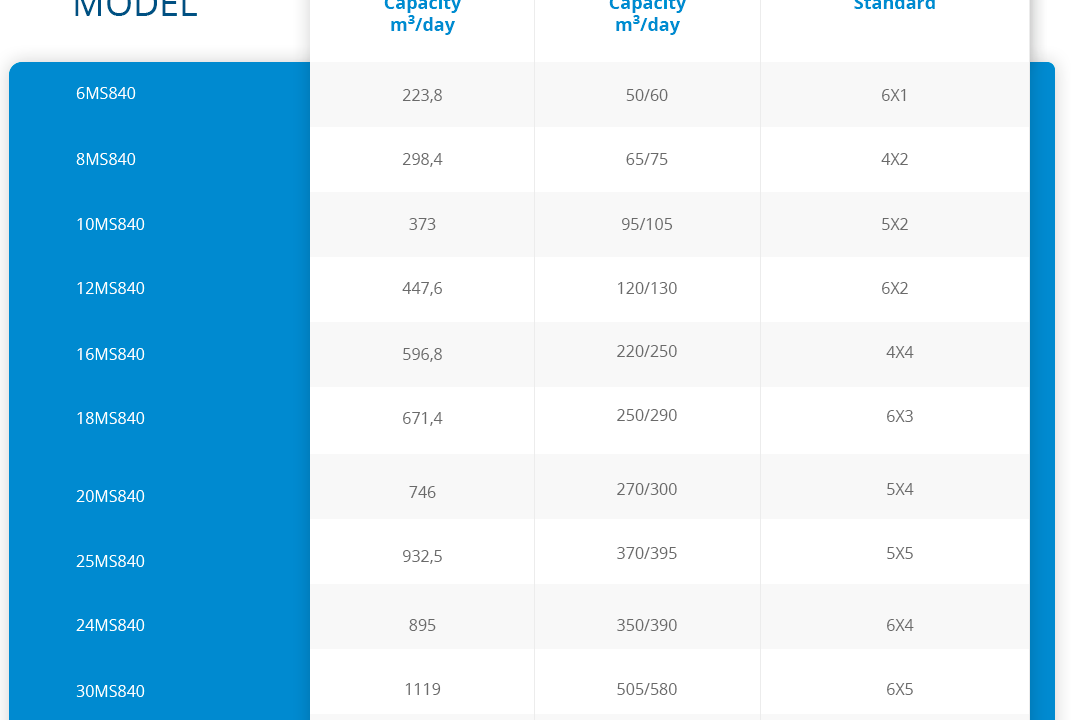

Technical Specifications

The pump to put seawater and brackish water under pressure for desalination which is the only part in movement and the electric power used to obtain a liter of fresh water is so low that this process is more cheaper than the desalination method based on evaporation and ion exchange.

- Membranes have an average endurance of more than 5 years.

- Maintenance required is more reduced.

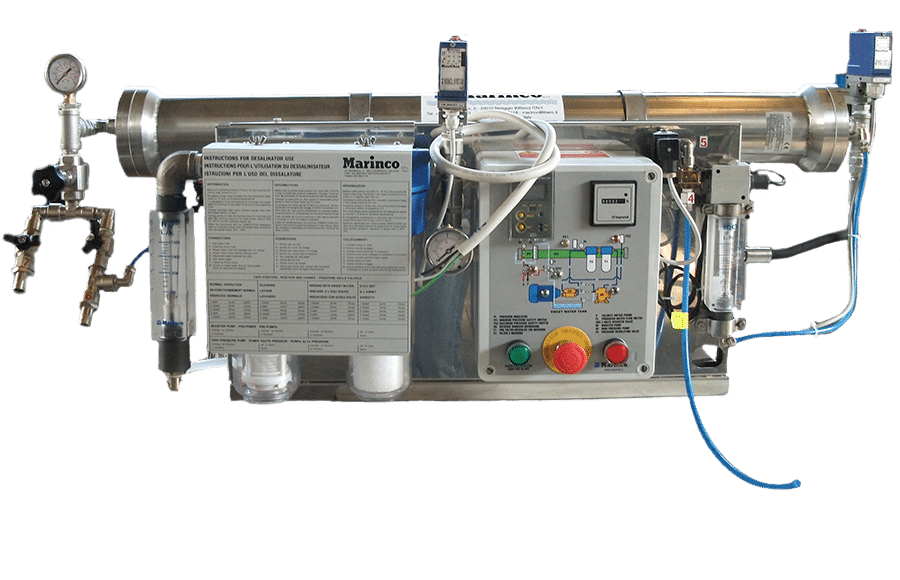

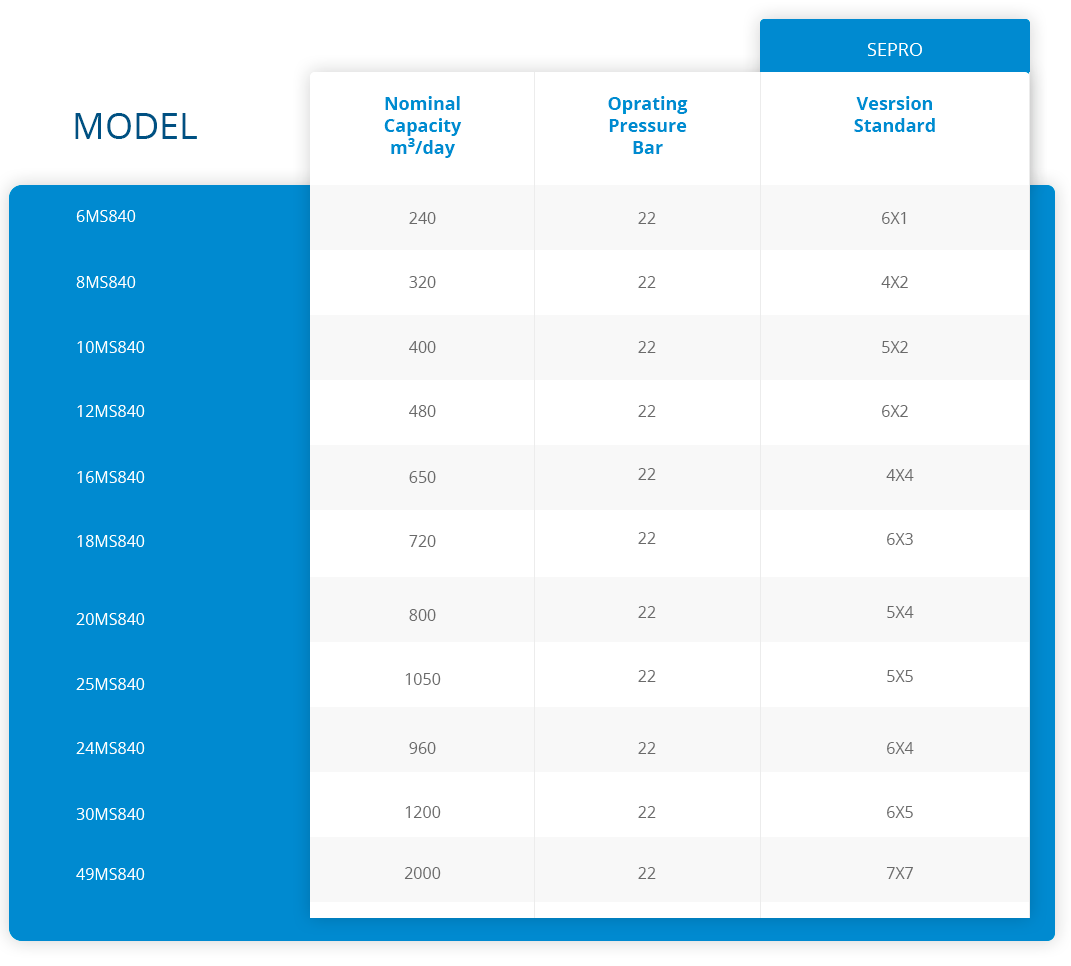

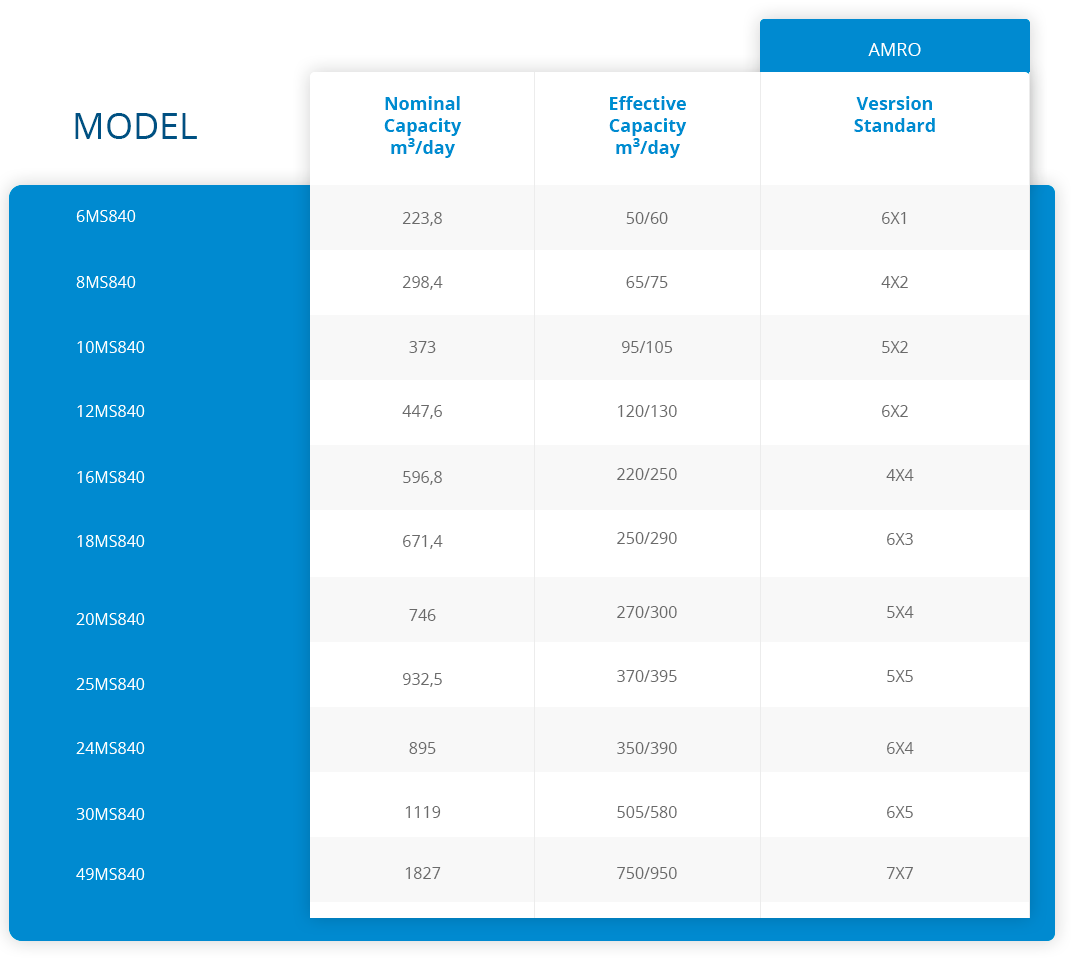

Desalinators Models

Marinco desalination plants can be used in different environments:

houses, resorts, hotels, restaurants, clubs and industries.

They are available in the following series:

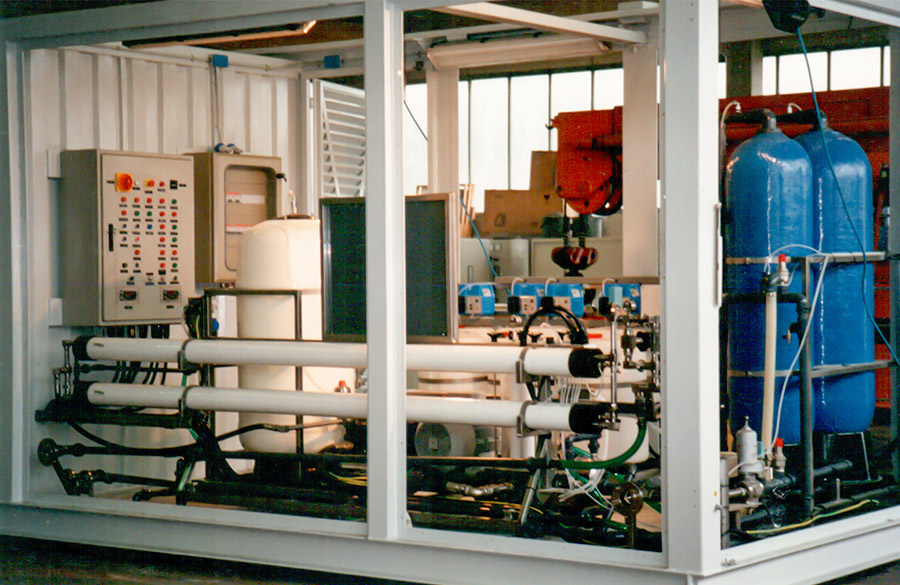

CONTAINERIZED UNIT

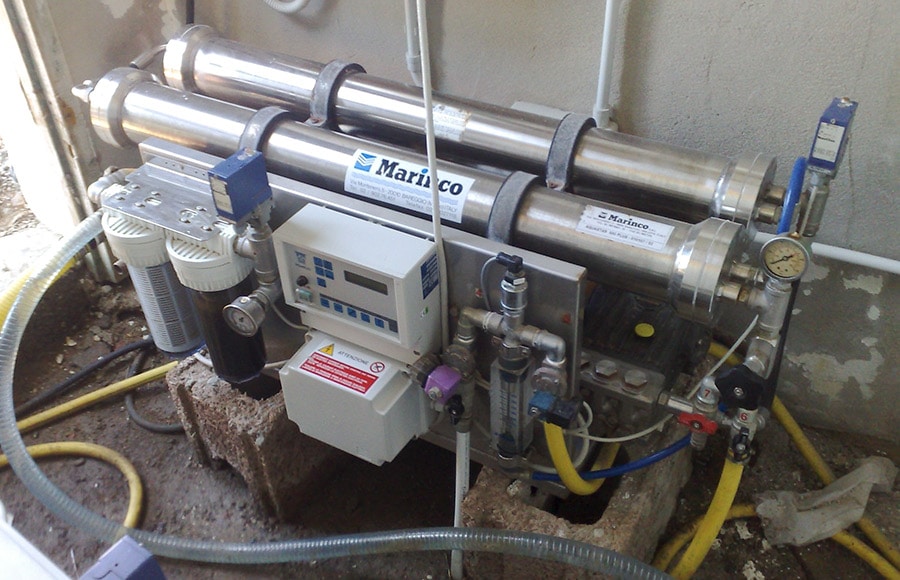

Marinco manufactures a comprehensive range of “containerized” or “skid mounted” desalination plants.

The containerized systems are built inside of metal shipping containers and are assembled and fully tested at our facility before being delivered with no need for on-site system assembly, pipe work, electrical wiring or mounting of components.

The container also serves as the shipping container so there is no need for wood crating or rental of sea containers in which to transport the system to its destination.

The complete system includes filtration, pumping equipment, membranes, electrical controls, and chemical feed and control components.

Our containerized units are designed to produce up to 1000M3/DAY of potable water from seawater.

Our containers are designed for indoor or outdoor, permanent or mobile installations.

Special customized containers can be provided, certified for offshore installation, in accordance to the stricts rules of DNV 2.7-1 and EN 12079-1 standards.